Transport and the Industrial Revolution

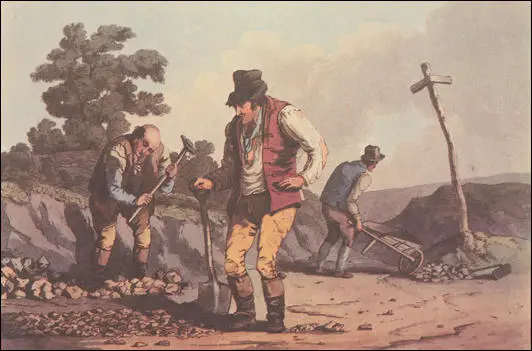

At the end of the 17th century, British roads were in a terrible state. A law passed in 1555 instructed local people to maintain the roads in their area. Every parish through which a road passed was legally bound to maintain it by six days a year of unpaid labour. In many area, this law was ignored. Even in those parishes where repairs were carried out, as there was no outside supervision, it was usually just a case of people putting stones and gravel in the worst potholes. Little, if any, attention was given to drainage, and so during the winter these roads often became a sea of mud. (1)

During this period coal was the most important cargo on British roads. In the 1670s around 2 million tons a year were being moved around Britain. Around one million tons by sea and a quarter of a million tons by inland rivers. Daniel Defoe, explained in his book, A Tour Through the Whole Island of Great Britain (1724) that to be successful, collieries needed to be close to water "for once the rains come in, it (the road) stirs no more that year, and sometimes a whole summer, is not dry enough to make roads passable". (2)

Hauliers came to collieries with horses and carts to collect coal. It is estimated that it would take ten pack-horses or a very large cart, to carry a ton of coal, so even a small colliery producing a few thousand tons a year would create a huge amount of traffic, often along unmade tracks. When bad weather made these tracks or roads impassable coal was left piled at collieries. (3)

In 1748 Pehr Kalm, the Swedish explorer visited England. He told a friend that he was very unimpressed with the quality of British roads: "In Sweden the road is higher than the land around, but here exactly the opposite is the case... In this country very large wagons are used with many horses... Through many years' driving, the wagons seem to have eaten down into the ground... to a depth of two, four, or six feet." (4)

The rapid increase in industrial production between 1700 and 1750 resulted in the need for an improved transport system. Whenever possible, factory owners used Britain's network of rivers to transport their goods. However, their customers did not always live by rivers and they therefore had to make use of Britain's roads. This was a major problem for mine-owners as transport costs were crucial. If they could not get their coal to market at a competitive price, they were out of business. (5)

The appalling state of Britain's roads created serious problems for factory owners. Bad weather often made roads impassable. When fresh supplies of raw materials failed to arrive, factory production came to a halt. Flooded roads also meant that factory owners had difficulty transporting the finished goods to their customers. Merchants and factory owners appealed to Parliament for help. After much discussion it was decided that this problem would only be solved if road building could be made profitable. Groups of businessmen were therefore encouraged to form companies called Turnpike Trusts. These companies were granted permission by Parliament to build and maintain roads. So that they could make a profit from this venture, companies were allowed to charge people to use these roads. Between 1700 and 1750 Parliament established over 400 of these Turnpike companies. (6) The quality of the roads built by these companies varied enormously. Some companies tried to increase their profits by spending very little money on repairing their roads. Other companies made every effort to provide a good service. In 1765, Harrogate Turnpike Trust employed John Metcalf to build a three-mile stretch of road in Yorkshire. Although blind since the age of six, Metcalfe was able to make an extremely good road. Metcalfe was aware of the importance of efficient drainage, and his decision to dig ditches along the sides of his convex roads considerably reduced the possibility of flooding. (7) This road was so successful he was commissioned to build a series of roads that were able to carry heavy wagons and withstand wet weather. According to Roger Osborne, the author of Iron, Steam and Money: The Making of the Industrial Revolution (2013) "Metcalf used rafts to build roads across bogs and was an astute surveyor, able to calculate materials and costs accurately. He went on building roads across the north of England, giving manufacturers and commercial travellers easier access to markets and canal and ports." (8) Another important road builder was Thomas Telford. This talented engineer adapted ideas first used by the Romans. On top of foundations made from large stone blocks, Telford spread layers of large and small stones. Telford's method was based on the idea that vehicles could assist rather than destroy roads. He pointed out that by using small stones on the surface of the road, the more traffic that used the road, the more tightly compacted the stones would become. Telford's roads were very impressive, but they were also expensive and the Turnpike companies found it difficult to make profits from this method of road building. (9) Eventually another Scottish engineer, John Macadam, came up with a cheaper method of making good roads. As he explained later: "I have generally made roads three inches higher in the centre than I have at the sides... if the road be smooth and well made, the water will run easily on such a slope... I always make my surveyors carry a pair of scales and a six ounce weight in their pocket and when they come to a heap of stones, they weigh one or two of the largest". (10) In 1816, Macadam was employed by the Bristol Turnpike Trust. Macadam developed the view that roads did not need stone foundations. His method was to spread a series of thin layers of small angular stones over a subsoil base. After each layer was laid, it was left for a while so that the weight of vehicles using the road could compact the stones together. These 'macadamized' roads enabled horses to pull three times the load they could on other road surfaces. Wagons and coaches could also travel much faster on this surface. (11) In the 18th century, Francis Egerton, the Duke of Bridgewater owned a large coal-mine at Worsley. The main market for his coal was the fast-growing town of Manchester. The roads between Worsley and Manchester were so bad that Bridgewater had to use pack-horses instead of wagons. As each horse could only carry 3 hundredweight (cwt) of coal at a time, this was a very expensive form of transportation. (12) In 1759, John Gilbert, one of Bridgewater's workers, suggested that a solution to this problem would be to cut a canal between Worsley Colliery and Manchester. Gilbert pointed out, that one horse could pull over 400 cwt of coal at a time when it was carried on a barge. Bridgewater liked the idea, and after gaining permission from Parliament gave instructions for the building of the Bridgewater Canal. (13) As Gavin Weightman, the author of The Industrial Revolutionaries (2007), has pointed out: "As there had been no tradition of canal-building before the 1750s, the engineers who took on the task had to learn new engineering skills - surveying the ground, determining the best course for the water and planning where locks and tunnels might be needed. In the eighteenth century the experts in the use of large-scale machinery were mostly millwrights - it was they who knew about cogs and gears and harnessing water power." (14) Bridgewater employed the talented engineer and millwright, James Brindley, to take charge of the project. It took Brindley eighteen months to build the ten-mile canal. At Worsley Colliery, Brindley constructed a network of underground waterways. Coal could now be loaded on barges at the coal face and transported direct to Manchester. With this new canal, Bridgewater was able to reduce the cost of his coal from 7d. to 4d. per cwt. When it was completed it became Britain's first industrial canal. (15) Bridgewater now extended his canal to the Mersey. This provided Manchester manufacturers with an alternative way of transporting their goods to the port of Liverpool. As this reduced the costs of transporting goods between these two cities from 12s to 6s a ton (20 cwt), Bridgewater had little difficulty in persuading people to use his canal. Samuel Smiles has argued that along with James Watt, Bridgewater "contributed to lay the foundations of the prosperity of Manchester and Liverpool... the cutting of the canal from Worsley to Manchester gave that town the immediate benefit of a cheap and abundant supply of coal; and when Watt's steam-engine became the great power in manufactures, such supply became absolutely essential to its existence as a manufacturing town." (16) The next venture was to connect this canal with "the Trent and the Potteries which needed heavy material, such as clay from Devon and Cornwall and flints from East Anglia, and whose products were at once too bulky and too fragile to be suitable for carriage by road." (17) The financial success of the Bridgewater Canal encouraged other business people to join together to build canals. Josiah Wedgwood, from Burslem, in Staffordshire, had been transporting his pottery by pack-horses. The poor state of the roads meant a great number of breakages. In 1766 Wedgwood and some of his business friends decided to recruit James Brindley to build the Trent & Mersey Canal. (18) The canal began within a few miles of the River Mersey, near Runcorn and finished in a junction with the River Trent in Derbyshire. It is just over ninety miles long with more than 70 locks and five tunnels. Although the canal cost £130,000 to build, it reduced the price of transporting Wedgwood's goods from £210s to 13s 4d a ton. The success of this canal resulted in Brindley being employed as the principal engineer on the Coventry Canal, the Oxford Canal, and the Staffordshire and Worcestershire Canal. (19) In his book, Inquiry into the Nature and Causes of the Wealth of Nations (1776), the economist Adam Smith pointed out that the improvement in transport was stimulating the economy: "Good roads, canals, and navigable rivers, by diminishing the expense of carriage, put the remote parts of the country more nearly upon a level with those in the neighbourhood of the town. They are upon that account the greatest of all improvements. They encourage the cultivation of the remote, which must always be the most extensive circle of the country. They are advantageous to the town, by breaking down the monopoly of the country in its neighbourhood. They are advantageous even to that part of the country. Though they introduce some rival commodities into the old market, they open many new markets to its produce." (20) Thomas Pennant, who toured Britain in 1779, agreed with Adam Smith and noted that the construction of canals had reduced the price of food and coal: "The fields, which before were barren, are now drained, and by the assistance of manure, conveyed on the canal toll-free, are clothed with a beautiful verdure. Places which rarely knew the use of coal are plentifully supplied with that essential article upon reasonable terms; and, what is of still greater public utility, the monopolizers of corn are prevented from exercising their infamous trade; for, communication being opened between Liverpool, Bristol, and Hull, and the line of canal being through countries abundant in grain, it affords a conveyance of corn unknown in past ages." (21) In an attempt to increase profits canals were now built all over Britain. By 1838 there were 2,200 miles of canal and 1,800 miles of navigable river. These waterways linked almost every factory and industrial town in Britain. This system of waterways also provided a route to Britain's ports and the profitable overseas market. At the same time, goods imported from the rest of the world could be efficiently distributed throughout Britain. (22) The growth in the use of steam engines in factories created a tremendous demand for coal. Where possible, coal was transported to the factory owners by canal or river. However, they still had the problem of finding an efficient way of getting the coal to the waterways. For a couple of hundred years, collieries had used wagonways to transport coal to the nearest waterway. This involved horses pulling carts on wooden tracks. Whereas a horse could normally only carry 3 cwt, by using wagonways or iron railroads a horse could pull over 3 tons (60 cwt). It is estimated that in the later 18th century there were 1,500 of these horse tramways in Britain. (23) The problem with horse-drawn railroads was that they were extremely slow. Richard Trevithick, a mining engineer from Cornwall, began experimenting with a steam locomotive that he hoped would eventually replace the horse. At first he concentrating on making a miniature locomotive and by 1796 had produced one that worked. The boiler and engine were in one piece; hot water was put into the boiler and a redhot iron was inserted into a tube underneath; thus causing steam to be raised and the engine set in motion. Trevithick now attempted to produce a much larger steam road locomotive and on Christmas Eve, 1801, it used it to take seven friends on a short journey. The locomotive's principle features were a cylindrical horizontal boiler and a single horizontal cylinder let into it. The piston, propelled back and forth in the cylinder by pressure of steam, was linked by piston rod and connecting rod to a crankshaft bearing a large flywheel. Trevithick's locomotive became known as the Puffing Devil but it could only go on short journeys as he was unable to find a way of keeping up the steam for any length of time. (24) Despite these early problems, Trevithick travelled to London where he showed several leading scientists, including Humphrey Davy, what he had invented. James Watt had been considering using this method to power a locomotive but had rejected the idea as too risky. Watt argued that the use of steam at high temperature, would result in dangerous explosions. Trevithick was later to accuse Watt and his partner, Matthew Boulton, of using their influence to persuade Parliament to pass a bill banning his experiments with steam locomotives. (25) In 1803 Samuel Homfray, the owner of the Penydarren Ironworks in Merthyr Tydfil, agreed to finance Trevithick's experiments. In February 1804, Trevithick produced the world's first steam engine to run successfully on rails. The locomotive, with its single vertical cylinder, 8 foot flywheel and long piston-rod, managed to haul ten tons of iron, seventy passengers and five wagons from the ironworks at Penydarren to the Merthyr-Cardiff Canal. During the nine mile journey the Penydarren locomotive reached speeds of nearly five miles an hour, but it was the power of the engine that mattered more than its speed of travel. (26) Trevithick's locomotive employed the very important principle of turning the exhaust steam up the chimney, so producing a draft which drew the hot gases from the fire more powerfully through the boiler. Trevithick's locomotive only made three journeys. Each time the seven-ton steam engine broke the cast iron rails. Homfray came to the conclusion that Trevithick's invention was unlikely to reduce his transport costs and so he decided to abandon the project. (27) John Blenkinsop was the manager of Middleton Colliery. Blenkinsop wanted to find a way of reducing the cost of transporting coal to the nearby town of Leeds. In 1811 Blenkinsop joined forces with Matthew Murray, an engineer, to produce a locomotive for the colliery. Blenkinsop wanted a locomotive that could be used to transport coal to Leeds. Blenkinsop and Murray rejected the idea that a steam locomotive with smooth wheels on a smooth rail would have sufficient adhesion to propel itself and a load. They therefore experimented with producing a rack railway. (28) The Salamanca (named after a battle in the Peninsular War) locomotive, with its cog-toothed driving wheels, first appeared in public on 24th June, 1812. The locomotive had two vertical cylinders within the top of the boiler, and the pistons drove the rack wheels through rods and pinions. The locomotive weighed 5 tons and on a level track was capable of hauling a load of 90 tons at 4 mph. Blenkinsop's locomotive was a great success and with Murray's help he produced three more. A local artist, George Walker, produced the first ever painting of a locomotive when he visited Middleton Colliery in 1814. (29) George Stephenson was also working on the problem of developing an effective steam-engine. The son of a colliery fireman, his family was so poor he did not attend school. George's first employment was herding cows but when he was fourteen he joined his father at the Dewley Colliery. George was an ambitious boy and at the age of eighteen he began attending evening classes where he learnt to read and write. (30) Like many colliery workers, he took on a variety of freelance jobs, notably clock-mending. At the age of twenty-seven, he found employment as an engineman at Killingworth Colliery. Every Saturday he took the engines to pieces in order to understand how they were constructed. This included machines made by Thomas Newcomen and James Watt. By 1812 Stephenson's knowledge of engines resulted in him being employed as the colliery's engine wright. (31) In 1813 Stephenson became aware of attempts by William Hedley and Timothy Hackworth, at Wylam Colliery, to develop a locomotive. Stephenson successfully convinced his colliery manager, Nicholas Wood, his to allow him to try to produce a steam-powered machine. By 1814 he had constructed a locomotive that could pull thirty tons up a hill at 4 mph. Stephenson called his locomotive, the Blutcher, and like other machines made at this time, it had two vertical cylinders let into the boiler, from the pistons of which rods drove the gears. Where Stephenson's locomotive differed from those produced by Blenkinsop, Hedley and Hackworth, was that the gears did not drive the rack pinions but the flanged wheels. The Blutcher was the first successful flanged-wheel adhesion locomotive. Stephenson continued to try and improve his locomotive and in 1815 he changed the design so that the connecting rods drove the wheels directly. These wheels were coupled together by a chain. Over the next five years Stephenson built sixteen engines at Killingworth. Most of these were used locally but some were produced for the Duke of Portland's wagonway from Kilmarnock to Troon. (32) Roger Osborne, the author of Iron, Steam and Money: The Making of the Industrial Revolution (2013) has argued: "Stephenson was a brilliant builder of locomotives, his greatest contribution was to bring engines and railways together. He improved the tracks, which were still liable to buckle or break even if they were made of cast iron, and worked to distribute the weight of the engines through more axles." (33) The owners of the colliery were impressed with Stephenson's achievements and in 1819 he was given the task of building an eight mile railroad from Hetton to the River Wear at Sunderland. While he was working on this Stephenson became convinced that to be successful, steam railways had to be made as level as possible by civil engineering works. The track was laid out in sections. The first part was worked by locomotives, this was followed by fixed engines and cables. After the railway reached 250 feet above sea level, the coal wagons travelled down over 2 miles of self-acting inclined plane. This was followed by another 2 miles of locomotive haulage. George Stephenson only used fixed engines and locomotives and had therefore produced the first ever railway that was completely independent of animal power. On 19th April 1821 an Act of Parliament was passed that authorized a company owned by Edward Pearse to build a horse railway that would link the collieries in West Durham, Darlington and the River Tees at Stockton. Stephenson arranged a meeting with Pease and suggested that he should consider building a locomotive railway. Stephenson told Pease that "a horse on an iron road would draw ten tons for one ton on a common road". Stephenson added that the Blutcher locomotive that he had built at Killingworth was "worth fifty horses". (34) That summer Edward Pease took up Stephenson's invitation to visit Killingworth Colliery. When Pease saw the Blutcher at work he realised George Stephenson was right and offered him the post as the chief engineer of the Stockton & Darlington company. It was now now necessary for Pease to apply for a further Act of Parliament. This time a clause was added that stated that Parliament gave permission for the company "to make and erect locomotive or moveable engines". Stephenson wrote to Pease: "I am glad to learn that the Parliament Bill has been passed for the Darlington Railway. I am much obliged by the favourable sentiments you express towards me, and shall be happy if I can be of service in carrying into execution your plans". (35) Stephenson began working with William Losh, who owned an ironworks in Newcastle. Together they patented their own make of cast iron rails. In 1821 John Birkinshaw, an engineer at Bedlington Ironworks, developed a new method of rolling wrought iron rails in fifteen feet lengths. Stephenson went to see these malleable rails and decided they were better than those that he was making with Losh. Although it cost him a considerable amount of money, Stephenson decided to use Birkinshaw's rails, rather than those he made with Losh, on the Stockton & Darlington line. In 1823 Edward Pease joined with Michael Longdridge, George Stephenson and his son Robert Stephenson, to form a company to make the locomotives. The Robert Stephenson & Company, at Forth Street, Newcastle-upon-Tyne, became the world's first locomotive builder. Stephenson recruited Timothy Hackworth, one of the engineers who had helped William Hedley to produce Puffing Billy, to work for the company. The first railway locomotive, Locomotion, was finished in September 1825. The locomotive was similar to those that Stephenson had produced at the collieries at Killingworth and Heaton. (36) Work on the track began in 1822. George Stephenson used malleable iron rails carried on cast iron chairs. These rails were laid on wooden blocks for 12 miles between Stockton and Darlington. The 15 mile track from the collieries and Darlington were laid on stone blocks. While building this railway Stephenson discovered that on a smooth, level track, a tractive force of ten pounds would move a ton of weight. However, when there was a gradient of 1 in 200, the hauling power of a locomotive was reduced by 50 per cent. Stephenson came to the conclusion that railways must be specially designed with the object of avoiding as much as possible changes in gradient. This meant that considerable time had to be spent on cuttings, tunnels and embankments. (37) The Stockton & Darlington line was opened on 27th September, 1825. Large crowds saw George Stephenson at the controls of the Locomotion as it pulled 36 wagons filled with sacks of coal and flour. The initial journey of just under 9 miles took two hours. However, during the final descent into the Stockton terminus, speeds of 15 mph (24 kph) were reached. The Durham County Advertiser reported: "The hour of ten arrived before all was ready to start. About this time the locomotive engine, or steam horse, as it was more generally termed, gave note of preparation. The scene, on the moving of the engine, sets description at defiance. Astonishment was not confined to the human species, for the beasts of the field and the fowls of the air seemed to view with wonder and awe the machine, which now moved onward at a rate of 10 or 12 mph with a weight of not less than 80 tons attached to it... The whole population of the towns and villages within a few miles of the railway seem to have turned out, and we believe we speak within the limits of truth, when we say that not less than 40 or 50,000 persons were assembled to witness the proceedings of the day." (38) The Stockton & Darlington line successfully reduced the cost of transporting coal. By 1825, locomotives on the railway were hauling trains of up to eighty tons at speeds of fifteen miles an hour. The reduction in his transport costs enabled Pearse to cut the price of his coal from 18s. to 8s. 6d. a ton. One newspaper reported that the "Stockton & Darlington rail-road, a work which will for ever reflect honour on its authors, for the new and striking manner in which it practically demonstrated all the advantages of the invention." (39) Before the establishment of the railway industry, most trading companies were owned by individuals, families or partnerships. However, vast sums were needed to build railways. One way that a railway company could raise this money was to form a joint stock company. For example, the Liverpool and Manchester Railroad Company calculated they would need over £400,000 (600 million in today's money) to build their railway. They obtained this money by persuading 308 people to buy 4,233 shares (at £100 a share) in the company. In 1824 the company published its prospectous: "The total quantity of goods passing between Liverpool and Manchester is estimated to be 1,000 tons per day... The average length of time taken (by canal) is 36 hours... The average charge... has been 15s a ton ... By the projected railroad, the transit of goods between Liverpool and Manchester will be 4 or 5 hours, and the charge to the merchant reduced by at least one-third." (40) The Quarterly Review supported the building of the Liverpool & Manchester Railway but urged the government to limit the speed of the locomotives: "What can be more palpably absurd than the prospect held out of locomotives travelling twice as fast as stagecoaches! We trust that Parliament will, in all railways it may sanction, limit the speed to eight or nine miles an hour." (41) The directors of the Liverpool & Manchester company were unsure whether to use locomotives or stationary engines on their line. To help them reach a decision, it was decided to hold a competition where the winning locomotive would be awarded £500. The idea being that if the locomotive was good enough, it would be the one used on the new railway. The competition was held at Rainhill during October 1829. Each competing locomotive had to haul a load of three times its own weight at a speed of at least 10 mph. The locomotives had to run twenty times up and down the track at Rainhill which made the distance roughly equivalent to a return trip between Liverpool and Manchester. Afraid that heavy locomotives would break the rails, only machines that weighed less than six tons could compete in the competition. Ten locomotives were originally entered for the Rainhill Trials but only five turned up and two of these were withdrawn because of mechanical problems. Sans Pariel and Novelty did well but it was the Rocket, produced by George and his son, Robert Stephenson, that won the competition. (42) The Liverpool & Manchester railway was opened on 15th September, 1830. Fanny Kemble was an invited guest to the proceedings: "The most intense curiosity and excitement prevailed, and though the weather was uncertain, enormous masses of densely packed people lined the road, shouting and waving hats and handkerchiefs as we flew by them. We travelled at 35 miles an hour (swifter than a bird flies). When I closed my eyes this sensation of flying was quite delightful. I had been unluckily separated from my mother in the first distribution of places, but by an exchange of seats which she was enabled to make she rejoined me when I was at the height of my ecstasy, which was considerably damped by finding that she was frightened to death, and intent upon nothing but devising means of escaping from a situation which appeared to her to threaten with instant annihilation herself and all her travelling companions." (43) The prime minister, the Duke of Wellington, and a large number of important people attended the opening ceremony that included a procession of eight locomotives. Unfortunately, when the train stopped at a halfway point to take on water, one of the government ministers, William Huskisson, got down from his carriage and stepped on to the parrallel track where he was hit by a locomotive travelling in the opposite direction. He died later that day. (44) Thomas Southcliffe Ashton has argued that "it was only with the newly constructed Liverpool and Manchester Railway, that the potentialities of steam transport were fully realized". (44) It soon became clear that large profits could be made by building railways and railways quickly became the basic infrastructure for the nation's transport. As they were built and run by individual companies at their own risk, the result was a fairly haphazard network, including many duplications of routes. (45) Most of the early railway companies were very successful. Shares in the Stockton and Darlington railway that were purchased for £100 in 1821 could be sold for £260 in 1838. The Liverpool and Manchester Railway Company regularly paid out an annual dividend of £10 for every £100 invested. By 1837 over eighty railway companies had plans to add to the network. That year over a thousand miles of track were laid down. (46) The railway system enabled manufacturers to transport their goods all over Britain. Farmers also benefited from the railways. Before the arrival of the railways, farmers could only sell perishable foodstuffs such as milk, butter and vegetables to local people. The railways made it possible to send food to the towns many miles away. (47) The railways, by lowering transport costs, also helped the growth in the export trade. Manufacturers used the railway network to transport their goods to the ports. The railway network also increased the circulation of newspapers and by using the railways instead of mail coaches, the post office was able to dramatically reduce the cost of sending a letter. Eventually the railway companies began to realise that they could make money by carrying passengers. The number of passengers carried increased from 5.5 million in 1838 to 30 million in 1845. One of the first railway excursions was run in 1841 from Sheffield to Derby with fares of 7s for first class, 5s for second class, and 4s for third class who travelled in open wagons. (48) Hippolyte Taine, a visitor from France, pointed out that while he was in Scotland, "I came across a cheap excursion train, its carriages crammed with people. They were all on the way to a religious meeting... where a number of famous preachers would be speaking... My neighbour told me there would be twenty thousand people at the meeting, some of them coming fifty or sixty miles." (49) At first, railway companies concentrated on transporting goods. However, it soon became clear that there was a large number of people who wanted to travel by rail. This is not surprising as trains were both quicker and cheaper than stage coaches. It was not long before railway companies were receiving more revenue from passengers than from carrying freight. Passenger trains usually contained first, second and third-class carriages. First-class carriages were completely enclosed and had padded seats, arm rests, and glass windows. These carriages were also fitted with springs to ensure a comfortable ride. Charles Grenville described his first train journey in 1837: "Nothing can be more comfortable than the vehicle in which I was put, a sort of chariot with two places, and there is nothing disagreeable about it but the occasional whiffs of stinking air which it is impossible to exclude altogether. The first sensation is a slight degree of nervousness and a feeling of being run away with, but a sense of security soon supervenes and the velocity is delightful. Town after town, one park and chateau after another are left behind with the rapid variety of a moving panorama, and the continual bustle and animation of the changes and stoppages make the journey very entertaining." (50) Second-class carriages had wooden benches and were open at the sides, while third-class carriages were just open trucks. One passenger complained: "We were put into a truck worse and more exposed than cattle trucks. There were seats, or forms to sit on, but they were swimming with rain." Louis Milroy Hayes described a journey he took in Manchester in 1840: "In these third-class carriages there was a general feeling of bare boards and cheerlessness as you entered them and if you were travelling in the winter time they gave you a kind of cold shiver... The seats were cushionless and the longer you sat on them the harder they seemed." (51) These high profits encouraged the formation of other railway companies. This rapid expansion of railways gave a tremendous boost to the iron and coal industries. It was also estimated that by the 1830s the railway companies were using over 200 million bricks a year. By 1855, over £300 million had been invested in British railway companies and 8,000 miles (12,800 kilometres) of track had been built. By 1860, the basic network of British railways was complete. (52) George Hudson, the Conservative MP for Sunderland became known as the Railway King. After buying a controlling interest in the North Midland Railway, he established the Great North of England Company so that they could complete the line from York to Newcastle-upon-Tyne. To obtain permission from the House of Commons, Hudson distributed over £3,000 in bribes. Hudson followed this by forming the Midland Railway Company. He now raised the sum of £5,000,000 to link the Midlands with Scotland. To persuade people to invest in the company he personally guaranteed the payment of a 6 per cent dividend. By 1844, Hudson's companies now controlled 1,016 miles of railway track. A survey in 1845 revealed that Hudson had £319,835 invested in railway shares. Hudson continued to buy shares in railway companies. He purchased a controlling interest in the Newcastle & North Shields Railway and the Great North of England Railway. It was later revealed that some of his share-dealings were not being entered in the company's account books. (53) George Hudson also began using inside information to manipulate share prices. In the short-term this made Hudson and his friends a great deal of money. However, railway shares were now over-priced and towards the end of 1847, their value began to fall dramatically. People who had heavily invested in railway shares faced financial ruin. A great deal of hostility was turned on the man who had persuaded them to buy shares and Hudson was forced to resign as chairman of all the railway companies under his control. (54) A committee of investigation was formed to look into Hudson's railway companies and it soon became clear that in the past he had not told potential buyers of shares, the truth about the real financial state of his companies. The investigators also discovered that Hudson had been paying bribes to MPs. Hudson had also sold shares he owned to the Great North Railway at inflated prices and had sold land to Newcastle & Berwick Railway that he did not own. George Hudson admitted these offences and agreed to pay back the money he had swindled from the shareholders. However, he did not pay back the money he owed to shareholders and in July 1865, was imprisoned in York Castle for debt. (55)Turnpike Trusts

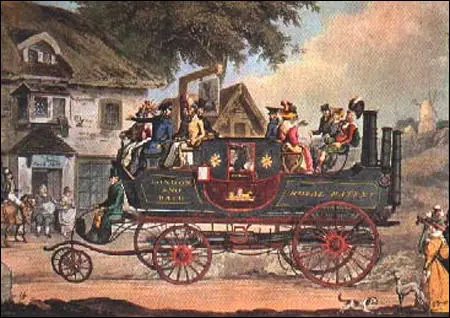

On its trips between London and Bath it reached an average speed of 15 m.p.h.Water Transport

Richard Trevithick

John Blenkinsop

George Stephenson

Liverpool & Manchester Railway

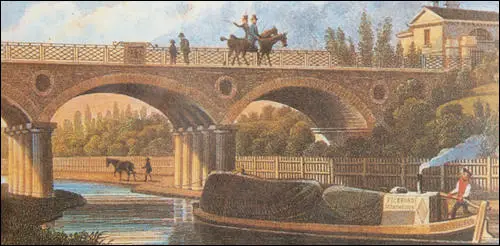

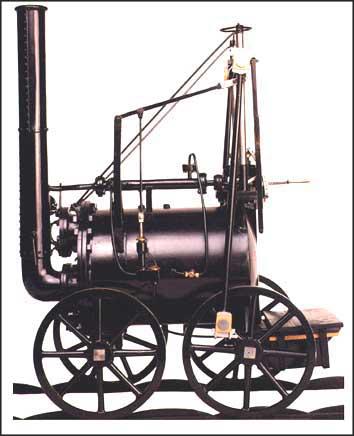

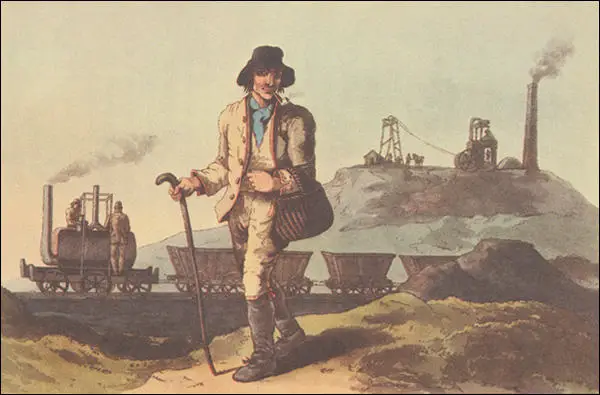

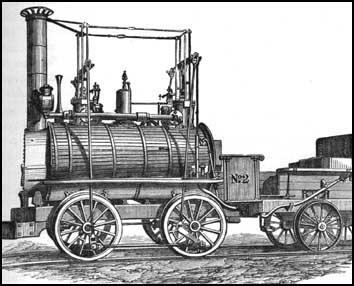

Railway Mania