Samuel Greg

Samuel Greg, the second son of Thomas Greg and Elizabeth Hyde, was born in Belfast in 1758. Samuel's father was a successful merchant and shipowner. His mother's family were also wealthy business people. Her brother, Robert Hyde, was a merchant based in Manchester. He imported linen yarns from Ireland and used weavers in Lancashire to turn it into cloth. The finished cloth was either sold locally or exported to America.

After a private education, Samuel Greg joined Robert Hyde's company in Manchester. In 1780, Hyde became a junior partner in his uncle's company. Two years later, Robert Hyde died, and Greg took over the firm. It was now a substantial business with the stock of cloth valued at £26,000.

By 1783 it became clear to Greg that his business needed a increasing quantity of good quality yarn. To guarantee this supply of yarn he decided to build his own textile mill. He chose a deep, wooden valley near Styal as the site of his first mill. One reason for this decision was that the River Bollin provided Greg with the power to drive his machinery.

Greg was a merchant and lacked technical expertise and employed Matthew Fawkner, to run Quarry Bank Mill when it opened in 1784. The mill had cost £3,000 to build and at first Greg employed 150 men to spin coarse yarn on water frames. The machines were powered by a water-mill of about 20 horse power.

In Manchester most of the textile merchants were Nonconformists. Most of Samuel's friends came from this group and in 1789 he married Hannah Lightbody, the daughter of Adam Lightbody, a Unitarian cotton merchant. Hannah shared her father's religious beliefs, and her liberal and humanitarian views had a considerable impact on her husband.

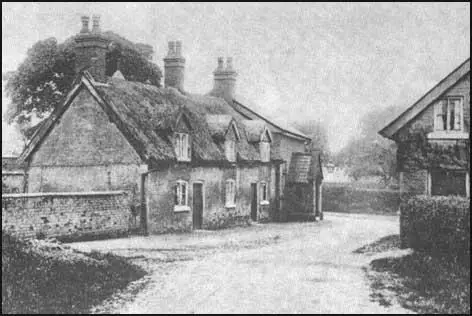

Hannah's dowry of £10,000 was invested in his Quarry Bank Mill. This paid for a replacement water-wheel and cottages for his growing work force at Style. Greg had difficulty finding enough people to work in his mill. Manchester was eleven miles away and local villages were very small. Imported workers needed cottages, and these cost about £100 each.

The cottages that Greg built for his workers were of a high standard. Each family (average of eight people per family) had a parlour, a kitchen, two bedrooms, a cistern and a backyard. Each cottage had a good-sized garden where they were encouraged to grow their own vegetables.

By 1790 Greg became convinced that the best solution to his labour problem was to build an Apprentice House and to purchase children from workhouses. The building for the apprentices cost £300 and provided living accommodation for over 90 children. At first the children came from local parishes such as Wilmslow and Macclesfield, but later he went as far as Liverpool and London to find these young workers. To encourage factory owners to take workhouse children, people like Greg were paid between £2 and £4 for each child they employed. Greg also demanded that the children were sent to him with "two shifts, two pairs of stockings and two aprons".The 90 children (60 girls and 30 boys) at Styal made up 50% of the total workforce. The children received their board and lodging, and two pence a week. The younger children worked as scavengers and piecers, but after a couple of years at Styal they were allowed to become involved in spinning and carding. Some of the more older boys became skilled mechanics.

Andrew Ure observed in The Philosophy of Manufactures (1835) "At Quarry Bank, near Wilmslow in Cheshire, is situated the great firm of Greg and Son. At a little distance from the factory, on a sunny bank, stands a handsome house, two stories high, built for the accommodation of the female apprentices. They are well fed, clothed and educated. The apprentices have milk-porridge for breakfast, potatoes and bacon for dinner, and meat on Sundays."

In 1796 recruited Peter Ewart as a partner. Ewart was an engineer who had been involved with James Watt and Matthew Boulton in the production of the early steam engines. Ewart's technical expertise was considered to be so important that Greg was willing to offer him a quarter of the spinning profits in return for an investment of £400 in the company.

Ewart arranged for the installation of a 10 horse-power Boulton & Watt steam engine. With this and two more water-wheels, Greg was in a position to buy spinning-mules for Quarry Bank. Greg continued to use water-frames for coarse yarn but the mules enabled him to produce finer yarns as well.

By 1816 Quarry Bank employed 252 people and was producing 342,578 pounds of cloth. Ten years later, the mill was employing 380 and output had reached 699,223 pounds. As well as taking a large share of the home market, Samuel Greg was also selling cloth to Italy, France, North America, Russia, Germany and South America.

The success of Quarry Bank Mill encouraged Greg to open mills at Caton (150 workers), Lancaster (560 workers), Bury (544 workers), Bollington (450 workers). By the time Samuel Greg died in June, 1834 his company was producing 0.6% of all yarn and 1.03% of all cloth produced in Britain.

Primary Sources

(1) In February 1817, the Vicar of Biddulph wrote a letter to Samuel Greg.

The thought has occurred to me that some of the younger branches of the poor of this parish might be useful to you as apprentices in your factory at Quarry Bank. If you are in want of any of the above, we could readily furnish you with 10 or more at from 9 to 12 years of age of both sexes.

(2) Return on capital invested in all the mills in Samuel Greg and Company.

Year

Return (%)

1819-20

14.8

1820-21

2.9

1821-22

13.4

1822-23

29.3

1823-24

28.5

1824-25

23.6

1825-26

9.5

1826-27

0.4

1827-28

18.0

1828-29

9.7

1829-30

10.9

(3) Return on capital invested in all the mills in Samuel Greg and Company.

Year

Employees

Cloth (lb)

Share of Market

1845

396

947,689

0.3

1850

377

720,169

0.2

1855

369

1,020,626

0.2

1860

365

946,705

0.1

1865

363

712,686

0.1

1870

356

1,075,889

0.1

1875

383

985,517

0.1

(4) M. R. Audubon, an American artist, visited Samuel Greg in 1826.

I accompanied Samuel Greg and William Greg to a debating club instituted on their premises for their workmen; on the way we passed a chapel and a low row of cottages for the work people and finally reached the schoolroom, where about 30 men had assembled. The question present was "which was the more advantageous, the discovery of the compass or that of the art of printing." I listened with interest and later talked with the men on some of the wonders of my own country in which they seemed much interested.

(5) Andrew Ure, The Philosophy of Manufactures (1835).

At Quarry Bank, near Wilmslow in Cheshire, is situated the great firm of Greg and Son. At a little distance from the factory, on a sunny bank, stands a handsome house, two stories high, built for the accommodation of the female apprentices. They are well fed, clothed and educated. The apprentices have milk-porridge for breakfast, potatoes and bacon for dinner, and meat on Sundays.