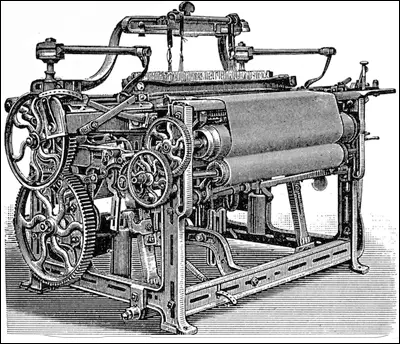

Power Loom

In 1784 Edmund Cartwright visited a factory owned by Richard Arkwright. Inspired by what he saw, he began working on a machine that would improve the speed and quality of weaving. Employing a blacksmith and a carpenter to help him, Cartwright managed to produce what he called a power loom. He took out a patent for his machine in 1785, but at this stage it performed poorly.

In 1787 Cartwright opened a weaving mill in Doncaster and two years later began using steam engines produced by James Watt and Matthew Boulton, to drive his looms. All operations that had been previously been done by the weaver's hands and feet, could now be performed mechanically. The main task of the weavers employed by Cartwright was repairing broken threads on the machine. Although these power looms were now performing well, Cartwright was a poor businessman and he eventually went bankrupt.

In 1802 William Horrocks, a Stockport cotton manufacturer, patented an improved power-loom. It featured a more effective way of winding the woven cloth onto a beam at the back of the loom. Over the next twenty years further improvements took place and by 1823 Richard Guest was able to claim that "a boy or girl aged fourteen or fifteen could manage two power-looms and could produce three and a half times as much as the best handloom weaver". By 1850 there were 250,000 cotton power-looms in Britain, of which nearly 177,000 were in Lancashire.