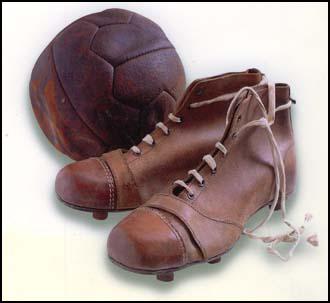

Football Boots

In the early 19th century footballers wore any pair of leather boots in their possession. Some players nailed bits of leather to their soles to give them a better grip during games. In 1863 the Football Association introduced Rule 13 that stated: "No one wearing projecting nails, iron plates or gutta percha on the soles of his boots is allowed to play."

In 1886 saw the introduction of studs. Ellis Patent Boot Studs advertised their product with a letter from a footballer who claimed that they were "a wonderful improvement in making football boots suitable for any weather." It was not until 1891 that the Football Association allowed boots to be fitted with studs. However, it was stipulated that they had to be "made of leather and did not project more than half an inch, and they had their fastenings driven in flush with the leather."

By the time that the Football League began in 1888 several companies were manufacturing specialised football boots. Boots were made of thick leather, which stretched above the ankle. The toe area was made of hardened leather as at the time it was usual for players to toe-kick the ball rather than use the instep. It was not long before all football boots were fitted with leather studs.

According to the The Encyclopedia of British Football: "Many players used to buy their boots on the small side and stand in a hot bath allowing them to expand, the aim being to mould the boot to suit the size of their feet." In 1937 the top amateur footballer, F. N. S. Creek, published his book, Association Football. He suggested that after buying a pair of football boots "sit on the edge of the bath with the boots soaking in tepid water for about half an hour". He then adds: "The boots are next allowed to dry slowly - not in front of the fire - and are finally well greased with dubbin."

Jackie Milburn was a coalminer in Ashington who joined Newcastle United in 1943. He points out in his autobiography that he used to wear a new pair of boots down the pit where conditions were often wet. Even after he became a full-time professional footballer he still used this strategy. He rejected the lightweight books given to him by the England management in 1950: "I always wore a size-six football boot even though my feet were size eight, so I used to break in a new pair by wearing them without socks and soaking them in cold water to mould them to my feet. I always preferred heavier soles to put some clout in my shots. Those new lightweights weren't for me." The author of this article remembers as a child in the 1950s being told by his father to wear his new football boots in the bath.

In the mid-1950s Adidas introduced boots with interchangeable screw-in studs made of rubber or plastic for varying weather conditions. Modern football boots are lightweight and are cut low around the ankle and have a soft toecap. This does expose the ankle to greater injury risk but top players argue that these new boots enable them to run faster and give them a "better feel of the ball".

Nike claim that the football boots made for Wayne Rooney called T90 Laser make use of the latest technology. High-motion cameras at 1,000-frames per second and reflective markers on Rooney's body allowed Nike to measure how his feet behaved when running, passing and shooting.

Then they evaluated how consistently he struck the ball using the shotshield technology on the sweet spot and how this influenced the direction through spin and power. Nike discovered that the strike is more powerful and its trajectory consistent when the biggest concentration of mass connects with the ball. Nike therefore placed rings, made of hardened plastic, to increase the density of the sweet spot. The sole of the boot was also made of a higher density material to stabilise the plant foot when shooting.