Steam Railways

The growth in the use of steam engines in factories created a tremendous demand for coal. Where possible, coal was transported to the factory owners by canal or river. However, they still had the problem of finding an efficient way of getting the coal to the waterways.

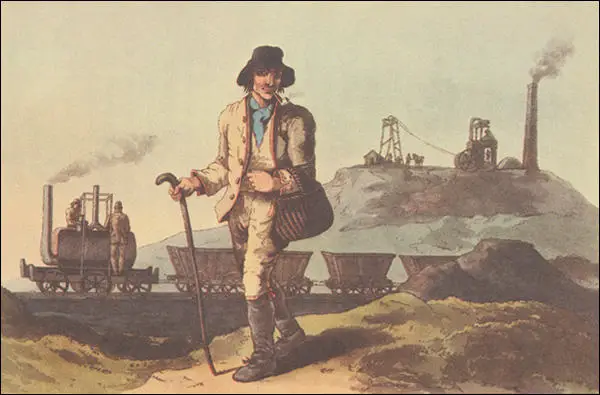

For a couple of hundred years, collieries had used wagonways to transport coal to the nearest waterway. This involved horses pulling carts on wooden tracks. Whereas a horse could normally only carry 3 cwt, by using wagonways or iron railroads a horse could pull over 3 tons (60 cwt). It is estimated that in the later 18th century there were 1,500 of these horse tramways in Britain. (1)

Richard Trevithick

The problem with horse-drawn railroads was that they were extremely slow. Richard Trevithick, a mining engineer from Cornwall, began experimenting with a steam locomotive that he hoped would eventually replace the horse. At first he concentrating on making a miniature locomotive and by 1796 had produced one that worked. The boiler and engine were in one piece; hot water was put into the boiler and a redhot iron was inserted into a tube underneath; thus causing steam to be raised and the engine set in motion.

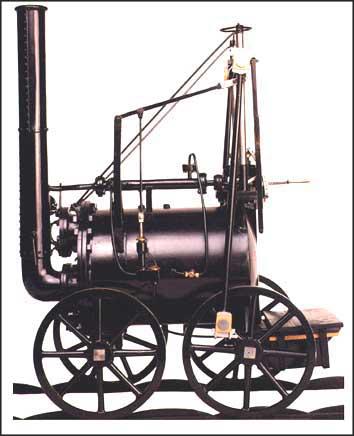

Trevithick now attempted to produce a much larger steam road locomotive and on Christmas Eve, 1801, it used it to take seven friends on a short journey. The locomotive's principle features were a cylindrical horizontal boiler and a single horizontal cylinder let into it. The piston, propelled back and forth in the cylinder by pressure of steam, was linked by piston rod and connecting rod to a crankshaft bearing a large flywheel. Trevithick's locomotive became known as the Puffing Devil but it could only go on short journeys as he was unable to find a way of keeping up the steam for any length of time. (2)

Despite these early problems, Trevithick travelled to London where he showed several leading scientists, including Humphrey Davy, what he had invented. James Watt had been considering using this method to power a locomotive but had rejected the idea as too risky. Watt argued that the use of steam at high temperature, would result in dangerous explosions. Trevithick was later to accuse Watt and his partner, Matthew Boulton, of using their influence to persuade Parliament to pass a bill banning his experiments with steam locomotives. (3)

In 1803 Samuel Homfray, the owner of the Penydarren Ironworks in Merthyr Tydfil, agreed to finance Trevithick's experiments. In February 1804, Trevithick produced the world's first steam engine to run successfully on rails. The locomotive, with its single vertical cylinder, 8 foot flywheel and long piston-rod, managed to haul ten tons of iron, seventy passengers and five wagons from the ironworks at Penydarren to the Merthyr-Cardiff Canal. During the nine mile journey the Penydarren locomotive reached speeds of nearly five miles an hour, but it was the power of the engine that mattered more than its speed of travel. (4)

Trevithick's locomotive employed the very important principle of turning the exhaust steam up the chimney, so producing a draft which drew the hot gases from the fire more powerfully through the boiler. Trevithick's locomotive only made three journeys. Each time the seven-ton steam engine broke the cast iron rails. Homfray came to the conclusion that Trevithick's invention was unlikely to reduce his transport costs and so he decided to abandon the project. (5)

John Blenkinsop

John Blenkinsop was the manager of Middleton Colliery. Blenkinsop wanted to find a way of reducing the cost of transporting coal to the nearby town of Leeds. In 1811 Blenkinsop joined forces with Matthew Murray, an engineer, to produce a locomotive for the colliery. Blenkinsop wanted a locomotive that could be used to transport coal to Leeds. Blenkinsop and Murray rejected the idea that a steam locomotive with smooth wheels on a smooth rail would have sufficient adhesion to propel itself and a load. They therefore experimented with producing a rack railway. (6)

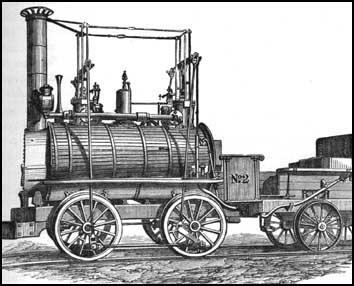

The Salamanca (named after a battle in the Peninsular War) locomotive, with its cog-toothed driving wheels, first appeared in public on 24th June, 1812. The locomotive had two vertical cylinders within the top of the boiler, and the pistons drove the rack wheels through rods and pinions. The locomotive weighed 5 tons and on a level track was capable of hauling a load of 90 tons at 4 mph. Blenkinsop's locomotive was a great success and with Murray's help he produced three more. A local artist, George Walker, produced the first ever painting of a locomotive when he visited Middleton Colliery in 1814. (7)

George Stephenson

George Stephenson was also working on the problem of developing an effective steam-engine. The son of a a colliery fireman, his family was so poor he did not attend school. George's first employment was herding cows but when he was fourteen he joined his father at the Dewley Colliery. George was an ambitious boy and at the age of eighteen he began attending evening classes where he learnt to read and write. (8)

Like many colliery workers, he took on a variety of freelance jobs, notably clock-mending. At the age of twenty-seven, he found employment as an engineman at Killingworth Colliery. Every Saturday he took the engines to pieces in order to understand how they were constructed. This included machines made by Thomas Newcomen and James Watt. By 1812 Stephenson's knowledge of engines resulted in him being employed as the colliery's engine wright. (9)

In 1813 Stephenson became aware of attempts by William Hedley and Timothy Hackworth, at Wylam Colliery, to develop a locomotive. Stephenson successfully convinced his colliery manager, Nicholas Wood, his to allow him to try to produce a steam-powered machine. By 1814 he had constructed a locomotive that could pull thirty tons up a hill at 4 mph. Stephenson called his locomotive, the Blutcher, and like other machines made at this time, it had two vertical cylinders let into the boiler, from the pistons of which rods drove the gears.

Where Stephenson's locomotive differed from those produced by Blenkinsop, Hedley and Hackworth, was that the gears did not drive the rack pinions but the flanged wheels. The Blutcher was the first successful flanged-wheel adhesion locomotive. Stephenson continued to try and improve his locomotive and in 1815 he changed the design so that the connecting rods drove the wheels directly. These wheels were coupled together by a chain. Over the next five years Stephenson built sixteen engines at Killingworth. Most of these were used locally but some were produced for the Duke of Portland's wagonway from Kilmarnock to Troon. (10)

Roger Osborne, the author of Iron, Steam and Money: The Making of the Industrial Revolution (2013) has argued: "Stephenson was a brilliant builder of locomotives, his greatest contribution was to bring engines and railways together. He improved the tracks, which were still liable to buckle or break even if they were made of cast iron, and worked to distribute the weight of the engines through more axles." (11)

The owners of the colliery were impressed with Stephenson's achievements and in 1819 he was given the task of building a eight mile railroad from Hetton to the River Wear at Sunderland. While he was working on this Stephenson became convinced that to be successful, steam railways had to be made as level as possible by civil engineering works. The track was laid out in sections. The first part was worked by locomotives, this was followed by fixed engines and cables. After the railway reached 250 feet above sea level, the coal wagons travelled down over 2 miles of self-acting inclined plane. This was followed by another 2 miles of locomotive haulage. George Stephenson only used fixed engines and locomotives and had therefore produced the first ever railway that was completely independent of animal power.

On 19th April 1821 an Act of Parliament was passed that authorized a company owned by Edward Pearse to build a horse railway that would link the collieries in West Durham, Darlington and the River Tees at Stockton. Stephenson arranged a meeting with Pease and suggested that he should consider building a locomotive railway. Stephenson told Pease that "a horse on an iron road would draw ten tons for one ton on a common road". Stephenson added that the Blutcher locomotive that he had built at Killingworth was "worth fifty horses". (12)

That summer Edward Pease took up Stephenson's invitation to visit Killingworth Colliery. When Pease saw the Blutcher at work he realised George Stephenson was right and offered him the post as the chief engineer of the Stockton & Darlington company. It was now now necessary for Pease to apply for a further Act of Parliament. This time a clause was added that stated that Parliament gave permission for the company "to make and erect locomotive or moveable engines". Stephenson wrote to Pease: "I am glad to learn that the Parliament Bill has been passed for the Darlington Railway. I am much obliged by the favourable sentiments you express towards me, and shall be happy if I can be of service in carrying into execution your plans". (13)

Stephenson began working with William Losh, who owned an ironworks in Newcastle. Together they patented their own make of cast iron rails. In 1821 John Birkinshaw, an engineer at Bedlington Ironworks, developed a new method of rolling wrought iron rails in fifteen feet lengths. Stephenson went to see these malleable rails and decided they were better than those that he was making with Losh. Although it cost him a considerable amount of money, Stephenson decided to use Birkinshaw's rails, rather than those he made with Losh, on the Stockton & Darlington line.

In 1823 Edward Pease joined with Michael Longdridge, George Stephenson and his son Robert Stephenson, to form a company to make the locomotives. The Robert Stephenson & Company, at Forth Street, Newcastle-upon-Tyne, became the world's first locomotive builder. Stephenson recruited Timothy Hackworth, one of the engineers who had helped William Hedley to produce Puffing Billy, to work for the company. The first railway locomotive, Locomotion, was finished in September 1825. The locomotive was similar to those that Stephenson had produced at the collieries at Killingworth and Heaton. (14)

Work on the track began in 1822. George Stephenson used malleable iron rails carried on cast iron chairs. These rails were laid on wooden blocks for 12 miles between Stockton and Darlington. The 15 mile track from the collieries and Darlington were laid on stone blocks. While building this railway Stephenson discovered that on a smooth, level track, a tractive force of ten pounds would move a ton of weight. However, when there was a gradient of 1 in 200, the hauling power of a locomotive was reduced by 50 per cent. Stephenson came to the conclusion that railways must be specially designed with the object of avoiding as much as possible changes in gradient. This meant that considerable time had to be spent on cuttings, tunnels and embankments. (15)

The Stockton & Darlington line was opened on 27th September, 1825. Large crowds saw George Stephenson at the controls of the Locomotion as it pulled 36 wagons filled with sacks of coal and flour. The initial journey of just under 9 miles took two hours. However, during the final descent into the Stockton terminus, speeds of 15 mph (24 kph) were reached.

The Durham County Advertiser reported: "The hour of ten arrived before all was ready to start. About this time the locomotive engine, or steam horse, as it was more generally termed, gave note of preparation. The scene, on the moving of the engine, sets description at defiance. Astonishment was not confined to the human species, for the beasts of the field and the fowls of the air seemed to view with wonder and awe the machine, which now moved onward at a rate of 10 or 12 mph with a weight of not less than 80 tons attached to it... The whole population of the towns and villages within a few miles of the railway seem to have turned out, and we believe we speak within the limits of truth, when we say that not less than 40 or 50,000 persons were assembled to witness the proceedings of the day." (16)

Liverpool & Manchester Railway

The Stockton & Darlington line successfully reduced the cost of transporting coal. By 1825, locomotives on the railway were hauling trains of up to eighty tons at speeds of fifteen miles an hour. The reduction in his transport costs enabled Pearse to cut the price of his coal from 18s. to 8s. 6d. a ton. One newspaper reported that the "Stockton & Darlington rail-road, a work which will for ever reflect honour on its authors, for the new and striking manner in which it practically demonstrated all the advantages of the invention." (17)

In 1826 Stephenson was appointed engineer and provider of locomotives for the Bolton & Leigh railway. He also was the chief engineer of the proposed Liverpool & Manchester railway. Stephenson was faced with a large number of serious engineering problems. This included crossing the unstable peat bog of Chat Moss, a nine-arched viaduct across the Sankey Valley and a two-mile long rock cutting at Olive Mount. (18)

The directors of the Liverpool & Manchester company were unsure whether to use locomotives or stationary engines on their line. To help them reach a decision, it was decided to hold a competition where the winning locomotive would be awarded £500. The idea being that if the locomotive was good enough, it would be the one used on the new railway.

The competition was held at Rainhill during October 1829. Each competing locomotive had to haul a load of three times its own weight at a speed of at least 10 mph. The locomotives had to run twenty times up and down the track at Rainhill which made the distance roughly equivalent to a return trip between Liverpool and Manchester. Afraid that heavy locomotives would break the rails, only machines that weighed less than six tons could compete in the competition. Ten locomotives were originally entered for the Rainhill Trials but only five turned up and two of these were withdrawn because of mechanical problems. Sans Pariel and Novelty did well but it was the Rocket, produced by George and his son, Robert Stephenson, that won the competition. (19)

The Liverpool & Manchester railway was opened on 15th September, 1830. Fanny Kemble was an invited guest to the proceedings: "The most intense curiosity and excitement prevailed, and though the weather was uncertain, enormous masses of densely packed people lined the road, shouting and waving hats and handkerchiefs as we flew by them. We travelled at 35 miles an hour (swifter than a bird flies). When I closed my eyes this sensation of flying was quite delightful. I had been unluckily separated from my mother in the first distribution of places, but by an exchange of seats which she was enabled to make she rejoined me when I was at the height of my ecstasy, which was considerably damped by finding that she was frightened to death, and intent upon nothing but devising means of escaping from a situation which appeared to her to threaten with instant annihilation herself and all her travelling companions." (20)

The prime minister, the Duke of Wellington, and a large number of important people attended the opening ceremony that included a procession of eight locomotives. Unfortunately, when the train stopped at a halfway point to take on water, one of the government ministers, William Huskisson, got down from his carriage and stepped on to the parrallel track where he was hit by a locomotive travelling in the opposite direction. He died later that day. (21)

Thomas Southcliffe Ashton has argued that "it was only with the newly constructed Liverpool and Manchester Railway, that the potentialities of steam transport were fully realized". (22) It soon became clear that large profits could be made by building railways and railways quickly became the basic infrastructure for the nation's transport. As they were built and run by individual companies at their own risk, the result was a fairly haphazard network, including many duplications of routes. (23)

Primary Sources

(1) The Quarterly Review (1825)

Can anything be more ridiculous than the claim that in the future locomotives will travel twice as fast as stage coaches.

(2) In 1841, Charles Young took a young friend, William Hinton, to see his first railway locomotive. When the locomotive went past, Hinton fainted.

When he recovered his feet... amazement was stamped upon his face. It must have been five minutes before he could speak... Well, sir, that was a sight to have seen; but one I never care to see again! How much longer shall knowledge be allowed to go on increasing.

(3) Speed (mph) for different forms of transport, 1780-1830

Date Transport Speed (mph)

1780 Horse-drawn barge on the Bridgewater Canal 4

1818 Pickford's horse-vans 6

1825 Manchester to London stage coach 10

1830 Stephenson's locomotive The Northumbrian 36

(4) Henry Booth, Account of the Liverpool and Manchester Railway (1830)

Perhaps the most striking result produced by the completion of this railway, is the sudden change which has been effected in our ideas of time and space... what was quick is now slow; what was distant is now near.

(5) In August, 1830, the actress Fanny Kemble travelled on a train for the first time.

We travelled at 35 miles an hour (swifter than a bird flies)... When I closed my eyes this sensation of flying was quite delightful... the motion was smooth... I could either have read or written... as it was I stood up, and... drank the air before me.

(6) In a letter that he wrote in November, 1829, the politician, Thomas Creevey, described travelling on a train for the first time.

During the five miles... we occasionally went at the rate of 23 miles an hour... The quick motion is to me frightful... It gave me a headache which has not left me yet... Although I am extremely glad indeed to have seen this miracle, and to have travelled in it... but having done so, I am quite satisfied with my first journey being my last.

(7) In 1836 George Head, described travelling on the Leeds and Selby Railway.

The country people could hardly have been more interested by the spectacle; the men at work in the fields stood like statues... every horse was on the alert, viewing the huge moving body as it approached with a mixture of fear and surprise... Even the cows spat out mouthfuls of unchewed grass and tried to gallop.

(8) Louis Milroy Hayes, Reminiscences of Manchester (1840)

In these third-class carriages there was a general feeling of bare boards and cheerlessness as you entered them and if you were travelling in the winter time they gave you a kind of cold shiver... The seats were cushionless and the longer you sat on them the harder they seemed.

Student Activities

Child Labour Simulation (Teacher Notes)

Road Transport and the Industrial Revolution (Answer Commentary)

Richard Arkwright and the Factory System (Answer Commentary)

Robert Owen and New Lanark (Answer Commentary)

James Watt and Steam Power (Answer Commentary)

The Domestic System (Answer Commentary)